Product FAQ

High-end CNC machine tool spindle bearings

High-end CNC machine tool bearing types include high-speed spindle bearing systems (including electric spindle bearings, dynamic and static pressure bearings), linear guide bearings, ball screws and other functional components. As a decisive factor in the machining accuracy of machine tools, these products have attracted great attention from machine tool manufacturers and machine tool users.

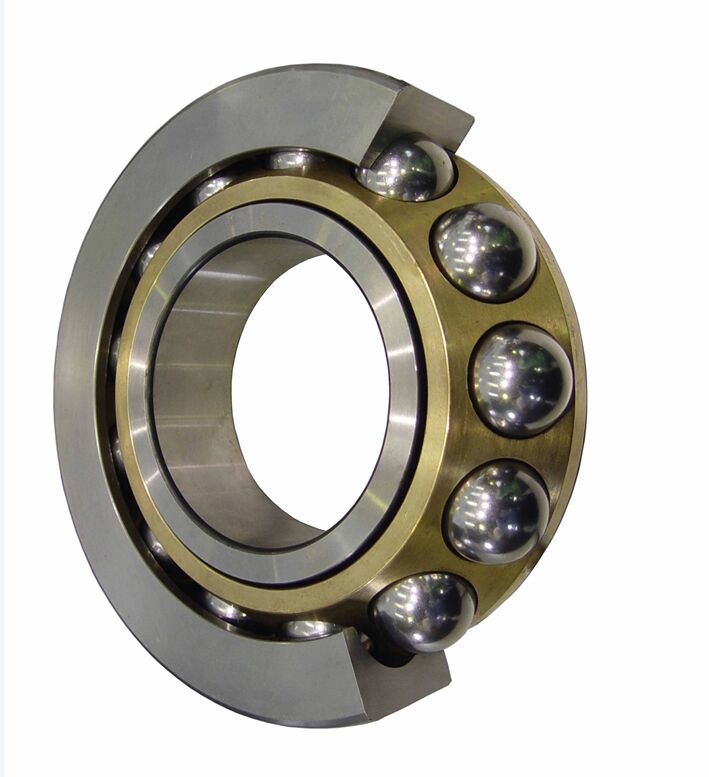

Among them, there are four main types of high-end CNC machine tool spindle bearings, namely: angular contact ball bearings, single and double row cylindrical roller bearings, single and double-direction thrust angular contact ball bearings, and traditional design tapered roller bearings.

Among CNC machine tool spindle bearings, precision angular contact ball bearings are mainly used in large-volume and wide-ranging applications.

The performance and product services of bearings are the main basis for customers to choose bearing products.

Precision and cutting capability are two important criteria for measuring the quality of machine tools. They depend on the overall design of the machine tool and, to a large extent, the machine tool workpiece spindle-bearing system. The structure and accuracy of the bearings determine the performance of the machine tool to a large extent. The spindle bearings of high-end CNC machine tools are rolling bearings with high-precision grades of P4 and above. As modern machine tools develop toward high precision, high efficiency, and high intelligence, new and higher requirements are constantly being put forward for machine tool spindle bearings, such as higher rotational accuracy, higher static and dynamic rigidity, and higher limits. speed, lower temperature rise and friction torque, and higher accuracy retention. At the same time, more reasonable and convenient installation and use, adjustment and maintenance, lubrication and sealing requirements are constantly being put forward. Integration, unitization and intelligence have become the technical development goals of CNC machine tool spindle bearings.

Categories

News

Contact Us

Contact: YRT Rotary Table Bearing|Crossed Roller Bearing|Luoyang Hongyuan Bearing 【HONB】

Phone: 13653797636

Tel: 400-037-9586

E-mail: lyhyzc7@gmail.com

Add: Chuangye road, Konggang Industrial cluster district,Luoyang city, Henan province, China